Health & Safety

Committed to Zero Harm

At Lundin Mining, we are committed to Zero Harm – Work Safe – Home Safe. Our objective is to provide our workforce with a safe, healthy, and productive work environment everywhere that we operate. Our Values of Safety, Respect, Integrity, and Excellence establish the foundation for our health and safety management approach. We believe that every injury is preventable, and our Zero Harm goal is to send everyone home healthy, safe, and well every day.

By continually striving to improve our health and safety work practices, we aim to make Lundin Mining safer every day. We recognize that our health and safety efforts can have a direct and positive effect on our stakeholders, including our employees, contractors, suppliers, and those who live and work in the communities where we operate. We work to set the example when it comes to health and safety, and we share safe work practices and any lessons learned with those impacted and all who are interested.

While we continue to monitor and support COVID-19 prevention and response efforts across our business, we are also working to continually improve our hazard identification, elimination, and control processes to support the prevention of occupational injuries, we are enhancing personal safety accountability across all levels of the organization, we are targeting a reduction in long term occupational health risk exposures, and we are progressing our fatality prevention efforts through engagement with industry peers and expert working groups.

While we continue to monitor and support COVID-19 prevention and response efforts across our business, we are also working to continually improve our hazard identification, elimination, and control processes to support the prevention of occupational injuries, we are enhancing personal safety accountability across all levels of the organization, we are targeting a reduction in long term occupational health risk exposures, and we are progressing our fatality prevention efforts through engagement with industry peers and expert working groups.

An Integrated Approach

Lundin Mining follows an integrated approach to health, safety, environment, and communities management through implementation of the company’s Responsible Mining Management System (RMMS) standard. The RMMS standard is aligned to ISO 14001 and ISO 45001 requirements and has been benchmarked against relevant aspects of the Mining Association of Canada’s Toward Sustainable Mining standard.

Key health and safety aspects of our RMMS implementation include workplace hazard identification, reporting and control requirements, qualitative and quantitative risk assessments, Life-Saving Rules, fatality prevention requirements called high consequence protocols, leadership training, fatality prevention training, safe work procedures and permit systems, safety interactions, safe work observations, incident reporting and investigation, root cause analysis, and sharing of lessons learned.

Occupational Health and Industrial Hygiene

Occupational health and industrial hygiene both play critical roles in our overall health and safety program. While our safety efforts focus on hazards that can result in an immediate incident or acute injury, our occupational health and industrial hygiene efforts aim to identify, monitor, and mitigate exposures to potential workplace hazards such as chemical, biological, physical, or ergonomic agents - hazards that can lead to acute illness or long-term chronic occupational disease.

Risk-based industrial hygiene programs are maintained at each of our operations and are focused on identifying and monitoring for potential exposures unique to their processes and operating environments. The programs also involve applying exposure-reduction plans that target our most significant agents (contaminants) of concern. When potential exposures are identified, we analyze the relevant risks and develop exposure-reduction strategies with mitigative measures based on the hierarchy of controls to reduce the potential risk to human health.

To support our occupational health efforts, each of our mining operations provide occupational health services to their employees either through on-site clinics or through local occupational medical providers or contracted mobile services.

Measuring Our Performance

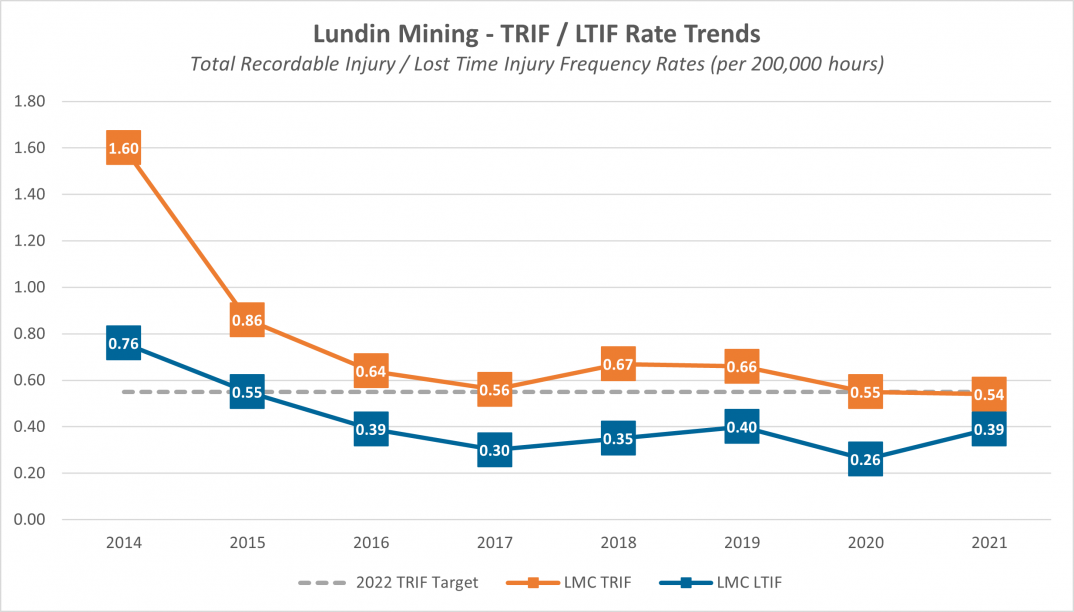

Our ongoing focus on culture, safety and leadership has helped us regularly improve our health and safety performance over the last decade. While measure our performance using a mix of leading and lagging indicators, the indicator used to measure overall performance and to benchmark against our industry peers is the Total Recordable Injury Frequency (TRIF) rate. We also use Lost Time Injury Frequency (LTIF) rate as a reference indicator. Our injury rates are calculated based on a 200,000-hour formula. LMC’s injury classification criteria are based on the International Council on Mining & Metals (ICMM) Health and Safety Performance Indicators (June 2021) manual and the Global Reporting Initiative (GRI) GRI 403-2018: Occupational Health & Safety standard and aligned to US Occupational Safety and Health Administration (OSHA) definitions for first aid and medical treatment for classification of recordable injuries. Use of this criteria ensures consistent reporting of occupational injuries and illnesses across LMC operations.

2021 Health and Safety Accomplishments

- Zero Fatalities

- Achieved Lundin Mining best ever TRIF rate of 0.54

Crisis Management Planning and Emergency Preparedness

We strive to maintain a high degree of emergency preparedness across Lundin Mining through implementation of our crisis management standard and crisis management plans. Our crisis management plans are supplemented by site-specific emergency response plans that cater to the unique aspects of each operation. Each operation maintains emergency response capabilities as well as a variety of firefighting and rescue equipment and specialized Personal Protective Equipment (PPE) that is suited to their needs and requirements.

Formal crisis management training and a mix of practice and desktop scenarios are conducted across the Company annually. Our operations-based emergency responders and mine rescue teams receive regular training on equipment and emergency response techniques. Practice exercises, simulated emergency scenarios and external training are regularly provided to ensure that team skills are maintained.

Implementation of our Pandemic Response Plan allowed us to continue providing a flexible and adaptive response to the COVID-19 pandemic as it has evolved since its emergence in Q1 of 2020. As a result, we have been able to effectively ensure the protection and support our workforce and our local communities while not experiencing significant business disruption.

Working Together

Teamwork, good leadership, employee involvement and a personal  commitment to health and safety are critical to achieving Zero Harm. Building on work originally started in 2015, we worked with DSS+ (formerly DuPont Sustainable Solutions) in 2021 to conduct a second company-wide safety culture perception survey to measure our safety culture against DuPont’s Bradley Curve™. More than 11,000 employee and contractor survey responses were submitted from across the Company. The 2021 survey results indicate that Lundin Mining’s safety culture remained strong throughout the period of the pandemic, with an overall Relative Culture Strength (RCS) score of 73 and placement in the Bradley Curve’s ‘interdependent’ category unchanged from the previous 2017 survey result. Learnings from the survey will be used to identify and refine areas for strategic health and safety improvement.

commitment to health and safety are critical to achieving Zero Harm. Building on work originally started in 2015, we worked with DSS+ (formerly DuPont Sustainable Solutions) in 2021 to conduct a second company-wide safety culture perception survey to measure our safety culture against DuPont’s Bradley Curve™. More than 11,000 employee and contractor survey responses were submitted from across the Company. The 2021 survey results indicate that Lundin Mining’s safety culture remained strong throughout the period of the pandemic, with an overall Relative Culture Strength (RCS) score of 73 and placement in the Bradley Curve’s ‘interdependent’ category unchanged from the previous 2017 survey result. Learnings from the survey will be used to identify and refine areas for strategic health and safety improvement.